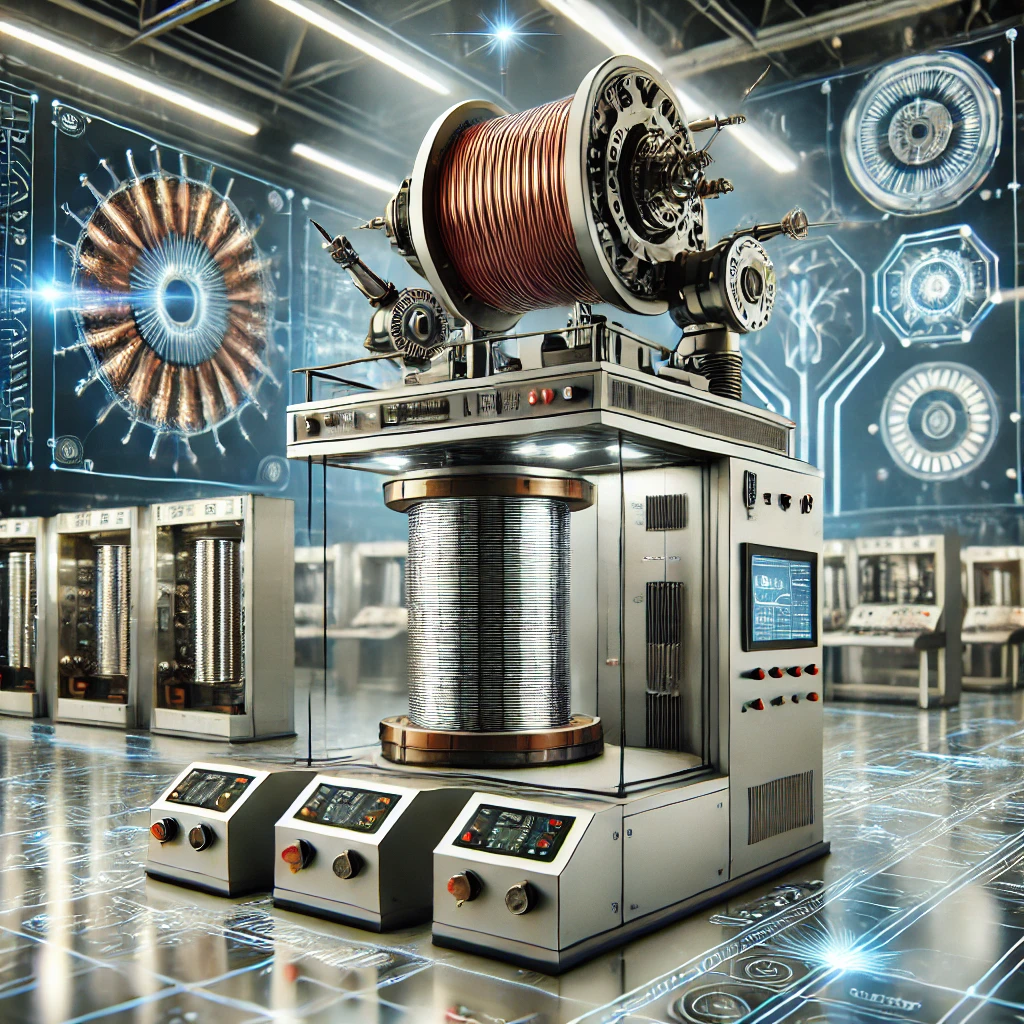

Introduction to Winding Factor

The winding factor is a critical concept in manufacturing, particularly in industries where precision is paramount. It refers to the efficiency and accuracy of how materials, typically wires or coils, are wound around a core or spool. This factor directly affects the performance, durability, and cost-efficiency of the end product. An optimized winding factor ensures that the materials are tightly and evenly wound, which is essential for the quality of the final product, especially in fields like aerospace, medical, and energy storage.

Understanding the winding factor is vital for companies like Guangri Electronic Machinery Co., Ltd, which specialize in precision winding machines. These machines rely on advanced winding techniques that ensure uniformity and consistency, which is crucial for creating high-performance components used across various industries. With the right winding factor, these machines can produce more reliable and durable products, driving innovation in the manufacturing process.

The Role of Guangri Electronic Machinery in Precision Winding

Guangri Electronic Machinery Co., Ltd is a leading Chinese manufacturer known for its expertise in precision winding machines. The company designs and manufactures advanced machines for a variety of industries, including aerospace, medical, and energy storage. Their state-of-the-art winding machines help optimize the winding factor, ensuring precision, efficiency, and consistency in every coil produced.

With years of experience and a commitment to technological innovation, Guangri has become a trusted partner for companies that require high-quality winding equipment. The company’s focus on precision allows them to meet the specific needs of industries that rely on the utmost accuracy, such as aerospace and medical sectors. Guangri’s winding machines not only improve productivity but also enhance the performance and longevity of the products they help create.

Winding Factor in Aerospace Industry Applications

In the aerospace industry, where reliability and performance are non-negotiable, precision winding is essential. Winding machines with a high winding factor play a pivotal role in the creation of aerospace components such as motors, transformers, and wiring systems. These components require accurate winding to function efficiently in the harsh conditions of air travel and space exploration.

Guangri’s winding machines meet the stringent standards of the aerospace industry. By ensuring that every coil is wound with utmost precision, these machines help create high-performance components that are essential for maintaining the integrity of aerospace technologies. With an optimized winding factor, Guangri ensures that aerospace products are not only functional but also capable of withstanding extreme conditions.

Medical Industry: Precision Winding for Critical Applications

In the medical industry, precision is even more critical, as the performance of components can have direct implications for patient health. Components like sensors, coils, and medical devices all require winding technology that is both highly precise and reliable. Guangri’s precision winding machines play a vital role in meeting the medical sector’s stringent requirements, helping manufacturers produce critical medical equipment with the necessary accuracy.

For instance, in the production of medical imaging devices, the winding of coils must be flawless to ensure accurate data transmission. Guangri’s advanced winding techniques guarantee that each coil is wound precisely, contributing to the accuracy and functionality of medical equipment. This focus on precision allows medical device manufacturers to provide higher-quality products that enhance patient care.

Energy Storage and Winding Technology

Energy storage is another area where the winding factor plays a crucial role. Devices like batteries and supercapacitors rely heavily on the accuracy of the winding process for optimal performance. A high-quality winding factor ensures that the energy storage units are efficient, long-lasting, and capable of maintaining charge for extended periods.

Guangri’s winding machines have become integral to the production of energy storage solutions. Their machines ensure that each coil is wound with precision, maximizing the efficiency and longevity of energy storage devices. In a world increasingly dependent on renewable energy sources and efficient power storage, Guangri’s machines are key to enabling the development of more effective energy solutions.

Advanced Winding Techniques and the Evolution of Winding Technology

Winding technology has come a long way over the years, with advancements in automation, robotics, and digital control systems transforming the way precision winding is achieved. Companies like Guangri are at the forefront of these innovations, continually pushing the boundaries of what is possible in winding technology. Modern machines now feature automated systems that ensure even greater precision, speed, and efficiency.

The evolution of winding technology has made it possible to create more complex, high-performance components for industries like aerospace, medical, and energy storage. Guangri’s commitment to innovation means they are constantly improving their machines, ensuring that the winding factor continues to play a crucial role in the production of high-quality, durable products across multiple sectors.

Conclusion: The Future of Winding Technology in Industry

The winding factor will continue to be an essential aspect of precision manufacturing in the future. As industries like aerospace, medical, and energy storage evolve, the need for more advanced and efficient winding technology will only grow. Companies like Guangri Electronic Machinery are poised to lead this charge, developing machines that not only meet today’s standards but also anticipate the future needs of these industries.

The future of winding technology promises even greater innovations, with smarter, faster, and more efficient machines that will shape the production of high-performance components for years to come. Guangri’s role in this ongoing evolution ensures that industries worldwide can rely on precision winding for the creation of products that are both high-quality and long-lasting.